Correlative microscopy

When should we use correlative microscopy approaches?

- Microstructures of advanced materials are becoming increasingly complex

- One characterization method alone is no longer capable of fully accounting for the complexity of these microstructures

- Each characterization method has its own advantages and disadvantages

- Combine several methods: overcome drawbacks of one particular method, use the advantages of several methods and merge the information obtained from various length scales and different complementary sources of information

Prime application example

- In a correlative approach, use more highly resolved methods (e.g., scanning electron microscopy) to gain additional information and establish references from these methods

- Correlative characterization is only needed for a limited subset of investigations

- References and insights gained allow to scale down to the simplest characterization method (e.g., light optical microscope) for series application

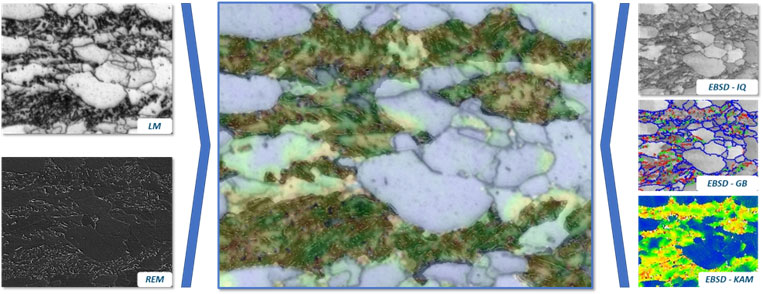

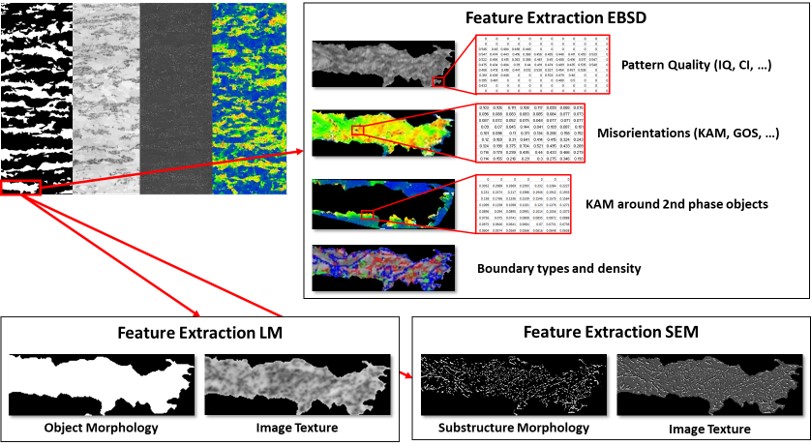

Combined LM, SEM and EBSD quantification of specified regions of interest

What we offer

- Correlative characterization including light microscopy (LM), scanning electron microscopy (SEM), electron backscatter diffraction (EBSD), energy-dispersive X-ray spectroscopy (EDX)

- Compilation of microstructure catalogs

- Benchmark of color etchings for LM analysis

- Use correlative characterization for machine learning

- Apply established references for a better, more objective, and reproducible ground truth assignment

- Which accuracies can be achieved by different methods? Which method is sufficient/necessary for a particular problem?

ThEtching

By using ThEtching, developed in collaboration with Cloeren Technologies, we can control microstructural contrasting in a targeted manner, follow it live on screen and record it. Staggered etching reactions can thus be continuously visualized and evaluated in a process.

You can see sample visualizations in the following video clips:

Contact for questions

Dr.-Ing Dominik Britz

Deputy Head MECS Saarbrücken

Adrian Thome, M. Sc

Project Leader

Further areas of application

Machine Learning (ML)

Our services range from feasibility studies with our various approaches to exploratory data analysis with unsupervised ML.

Triboelectrical characterization

Complementary to our microstructure analysis, we are able to perform a wide variety of triboelectric measurements (e.g. electrical resistivity and coefficient of friction during mating tests) under controlled conditions.

Failure analysis

In the area of failure analysis, in addition to identifying and analyzing causes of fracture, we are also able to fully characterize components on both the macro and micro scales.

Antimicrobial surfaces

Our antimicrobial metallic surfaces have already been used in 3 research projects with ESA & NASA on the ISS.

You are interested in working with us?

Feel free to contact us! We look forward to talking to you and finding out how we can help you with your project.