Classification of the carbon-rich second phase in dual-phase steels

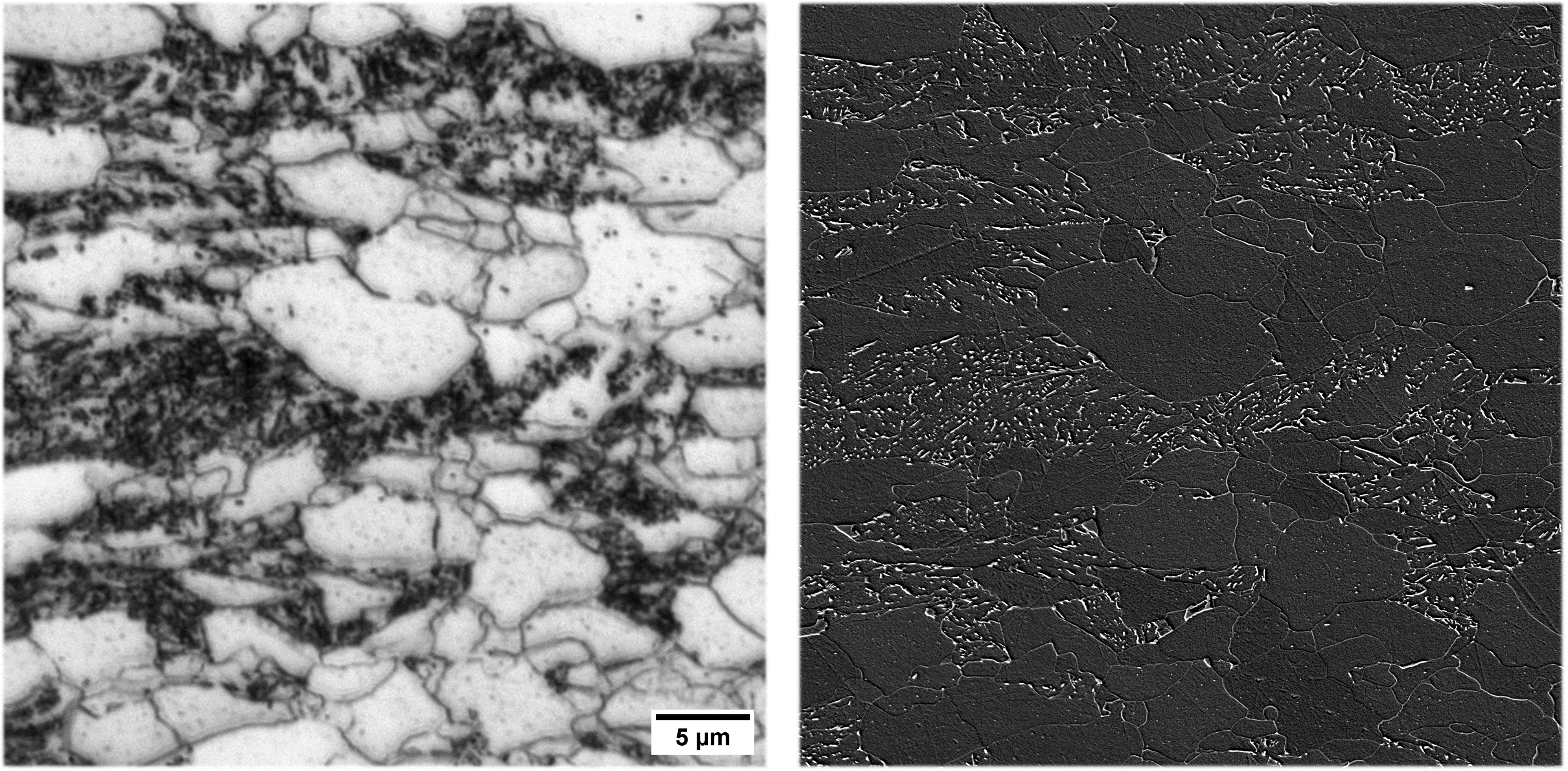

Carbon-rich second phase in dual phase steel

- Sample of a multiphase steel with polygonal ferrite, bainite and carbon-rich second phases

- Preparation and contrasting with modified Beraha etching

- Images in the light microscope (LM) and scanning electron microscope (SEM)

Task definition:

- Depending on the chemical composition and production parameters, the carbon-rich second phase in dual-phase steels can consist of pearlite, bainite or martensite

- The bainitic microstructures can in turn be subdivided into various subclasses. As manual differentiation of these bainite subclasses is error-prone and difficult to reproduce, classification is realised using machine learning (ML)

Realization:

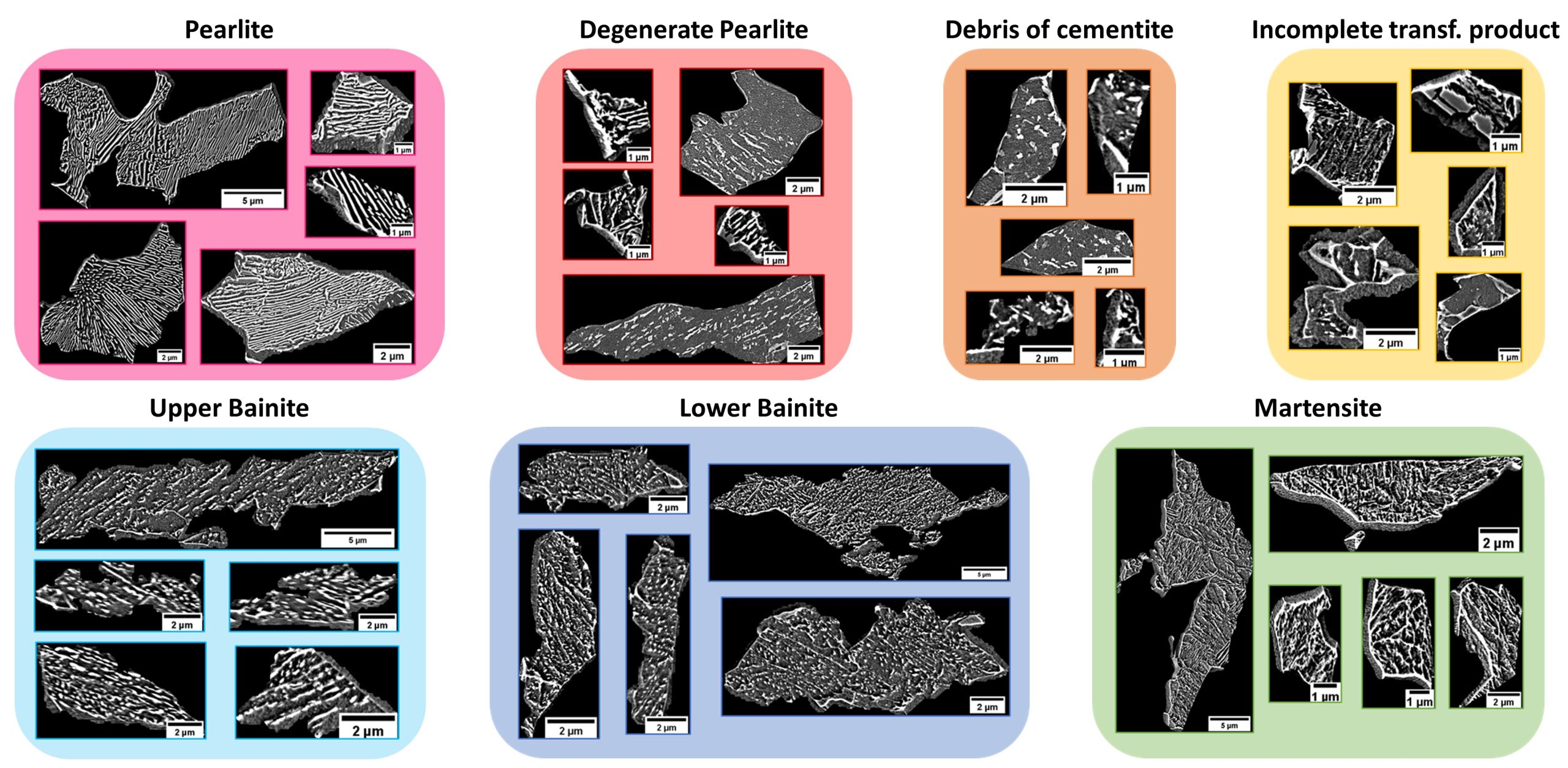

- Object-by-object classification using conventional ML. Scanning electron microscope (SEM) images are used. Image texture parameters and morphological parameters are used as distinguishing features between the microstructural components

- Use of correlative microscopy (SEM and electron backscatter diffraction) for objective ground truth

- 7 classes are taken into account: Pearlite, 5 different types of bainite and martensite

Carbon rich second phase in dual phase steels

Results:

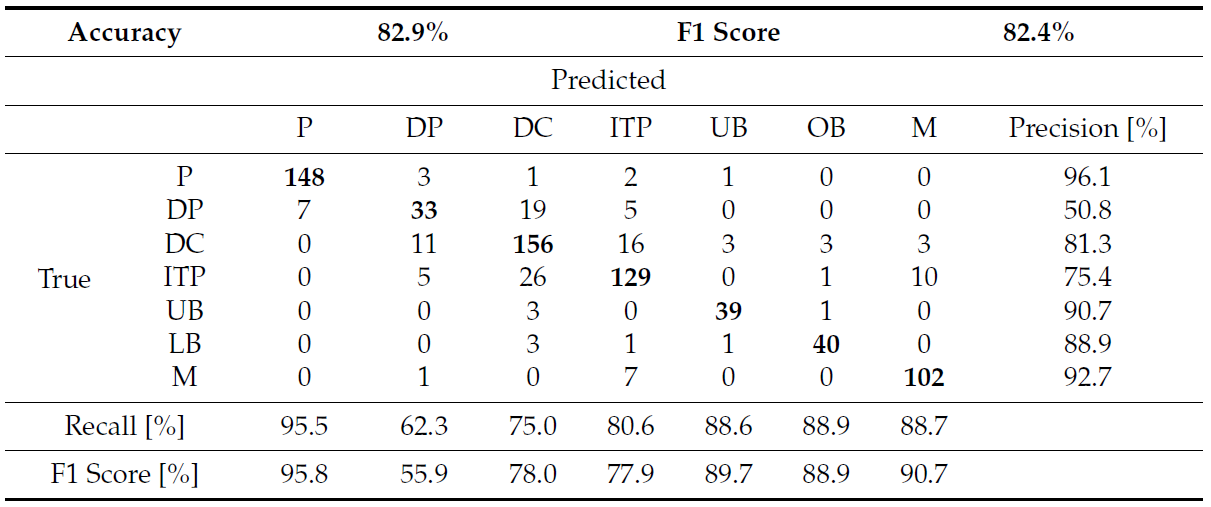

- The ML model achieves a classification accuracy of 82.9 %, which is an outstanding value considering the complexity of bainitic structures

- The classes pearlite, martensite and upper and lower bainite can even be recognised with 90 % accuracy

Fields of application:

- Automated, objective and reproducible microstructure classification

- This new level of detail in microstructure classification enables improved quantification as the basis for new process-structure property correlations

Partners of cooperation:

- Joint-stock company of Dillinger Huettenwerke, Dillingen/Saar

References:

- Müller, M., Britz, D., Staudt, T., & Mücklich, F. (2021). Microstructural Classification of Bainitic Subclasses in Low-Carbon Multi-Phase Steels Using Machine Learning Techniques. Metals, 1836(11). https://doi.org/https://doi.org/10.3390/met11111836

- Gola, J., Webel, J., Britz, D., Guitar, A., Staudt, T., Winter, M., & Mücklich, F. (2019). Objective microstructure classification by support vector machine (SVM) using a combination of morphological parameters and textural features for low carbon steels. Computational Materials Science, 160 (January), 186–196. https://doi.org/10.1016/j.commatsci.2019.01.006

- M. Azimi, D. Britz, M. Engstler, M. Fritz, F. Mücklich, Advanced steel microstructural classification by deep learning methods, Sci. Rep. 8 (2018) 1–14. https://doi.org/10.1038/s41598-018-20037-5

Contact

Dr.-Ing. Dominik Britz

Deputy Head MECS Saarbrücken

Adrian Thome, M.Sc.

Chief Operating Officer

You are interested in working with us?

Feel free to contact us! We look forward to talking to you and finding out how we can help you with your project.