Microstructure classification in heat-treatable steels

Task definition:

- The differentiation between bainite and martensite in tempered structures is still often carried out manually and purely qualitatively

- A purely light microscopic evaluation and in particular a differentiation between martensite, (self-)tempered martensite and lower bainite, which can all occur simultaneously, is highly subjective and error-prone

- Instead, a classification is to be realised using Machine Learning (ML)

Realization:

- A travelling window splits the micrograph into individual sections, which are then classified by a Deep Learning (DL) model

- Training of separate models for LM and SEM images

- Use of correlative microscopy (LM/SEM and electron backscatter diffraction) for objective ground truth

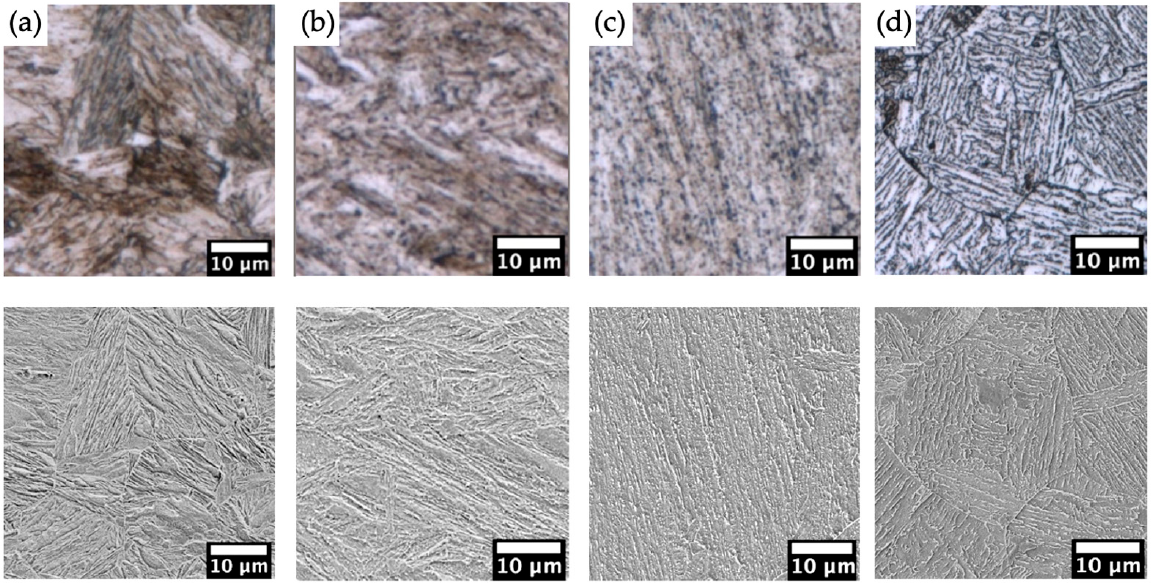

- In this application example, 4 classes are considered: (a) Martensite, (b) (self-) tempered martensite, (c) lower bainite, and (d) upper bainite

4 classes for LM/SEM and electron backscatter diffraction, from Bachmann et al., (2023)

Results:

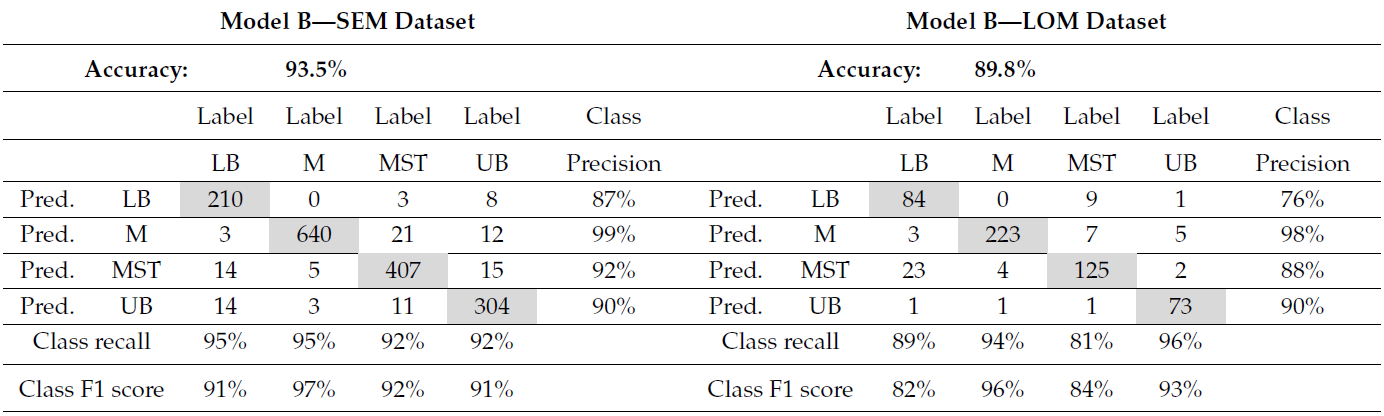

- The models for sectional classification achieve accuracies of 93.5 % for SEM images and 89.8 % for LM images. Considering the complexity of the microstructure and the limited LM resolution, these are outstanding values

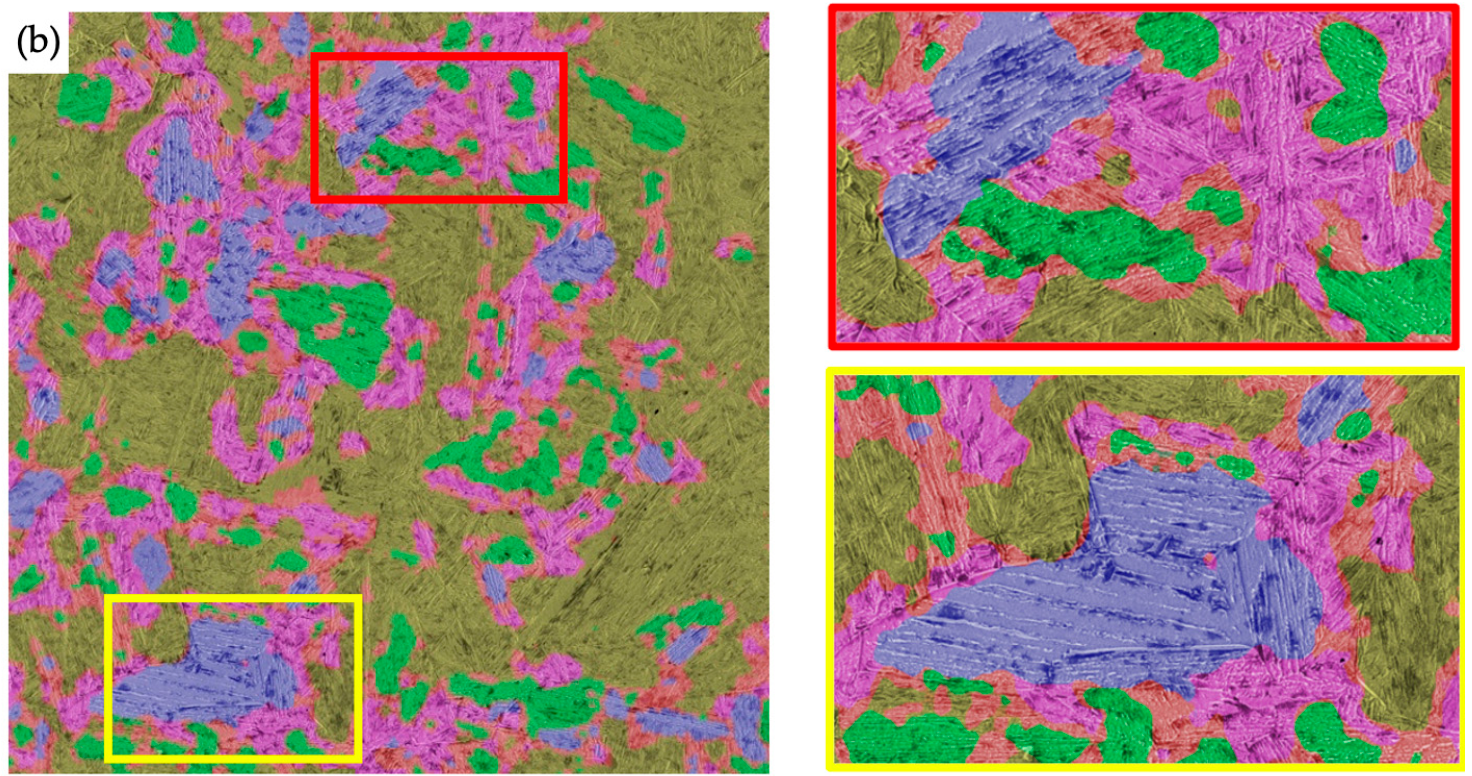

- The travelling window approach also enables good segmentation of entire unseen images

LM /REM recording from Bachmann et al., (2023)

Areas of application:

- Automated, objective and reproducible microstructure classification

- This new level of detail in microstructure classification enables improved quantification as the basis for new process-structure property correlations

- The correlative data enables a systematic investigation of the application limits of LM and the required resolutions

Partners for cooperation:

- Aktien-Gesellschaft der Dillinger Hüttenwerke, Dillingen/Saar

References:

- Bachmann, B., Müller, M., Britz, D., Staudt, T., & Mücklich, F. (2023). Reproducible Quantification of the Microstructure of Complex Quenched and Quenched and Tempered Steels Using Modern Methods of Machine Learning. Metals, 13(1395), 1–27. https://doi.org/https://doi.org/10.3390/met13081395

Contact

Dr.-Ing. Dominik Britz

Deputy Head MECS Saarbrücken

Adrian Thome, M.Sc.

Chief Operating Officer

You are interested in working with us?

Feel free to contact us! We look forward to talking to you and finding out how we can help you with your project.