Triboelectrical characterization

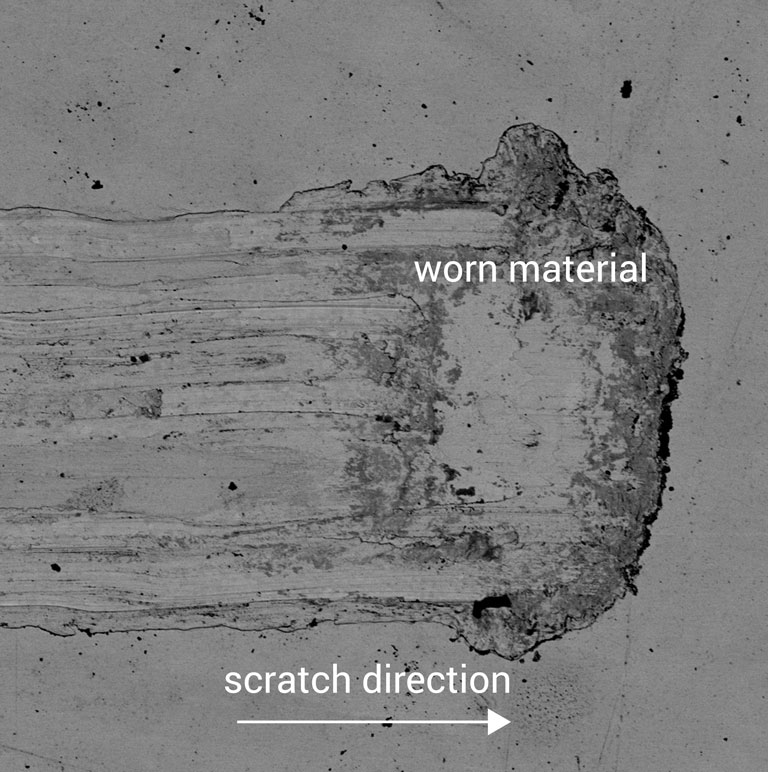

Fretting

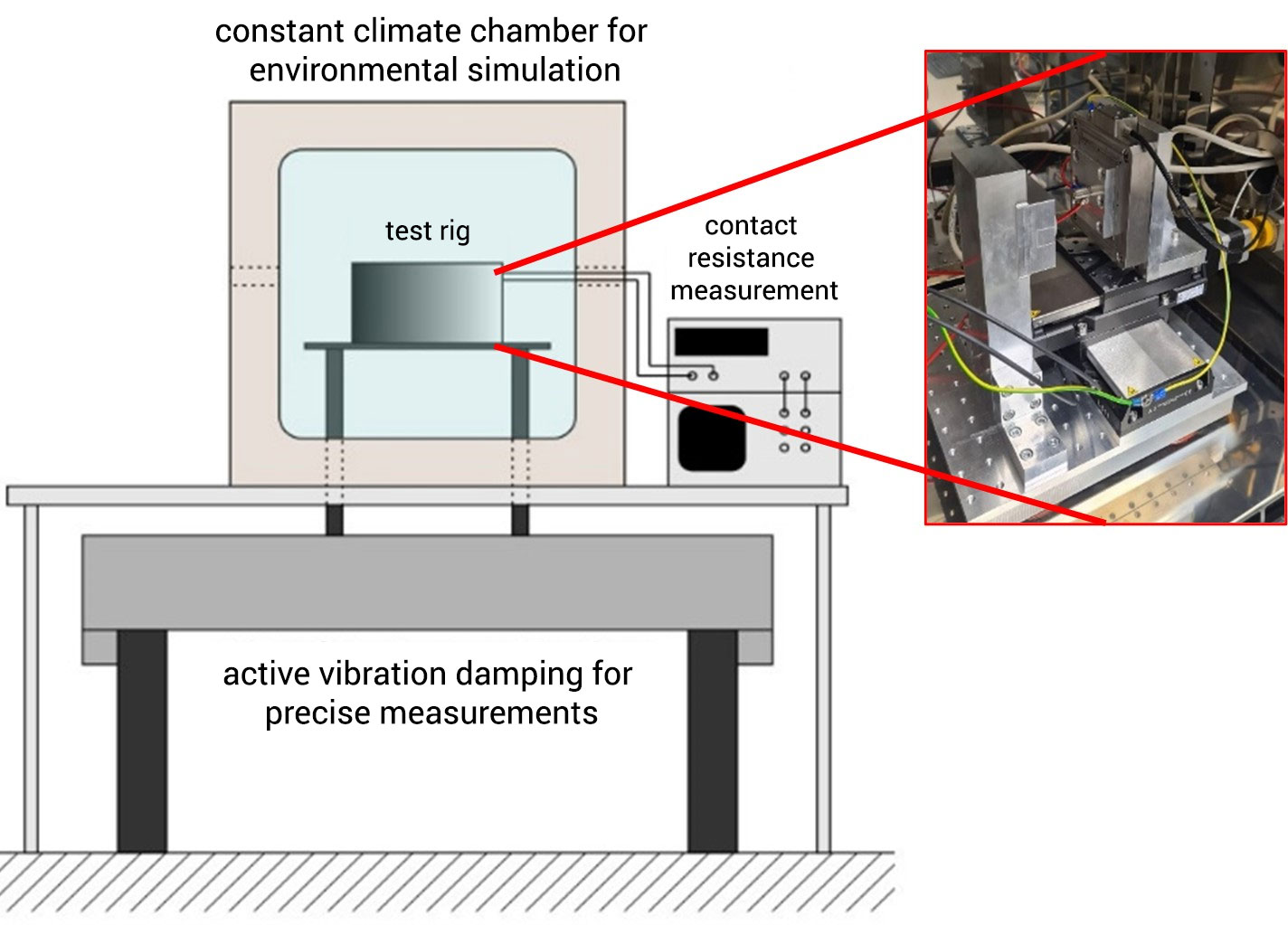

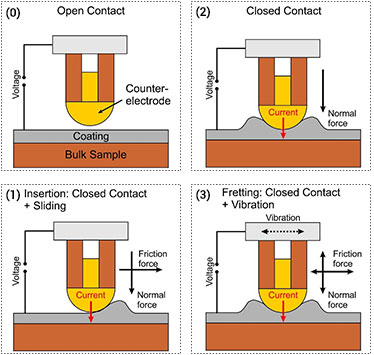

Complementing our microstructure analysis, we are able to perform the following triboelectric measurements under controlled conditions to ensure that the stringent requirements for these parts are met:

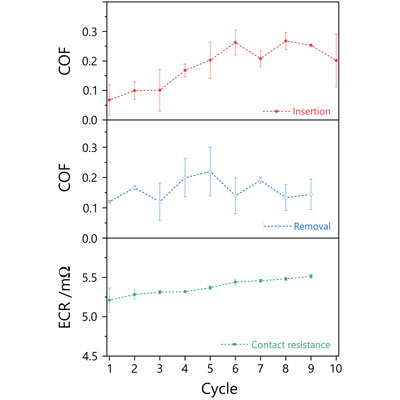

- Eletrical contact resistance (ECR)

- Insertion force (including normal force, friction force and coefficient of friction for one or multiple insertion cycles)

- Current sweep

- Electrical arc discharge

- Indentation

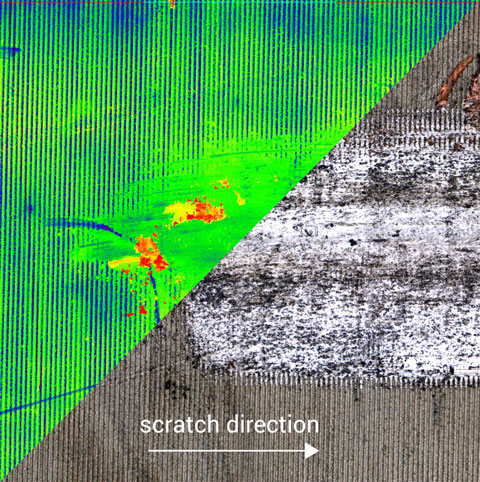

- Scratch test

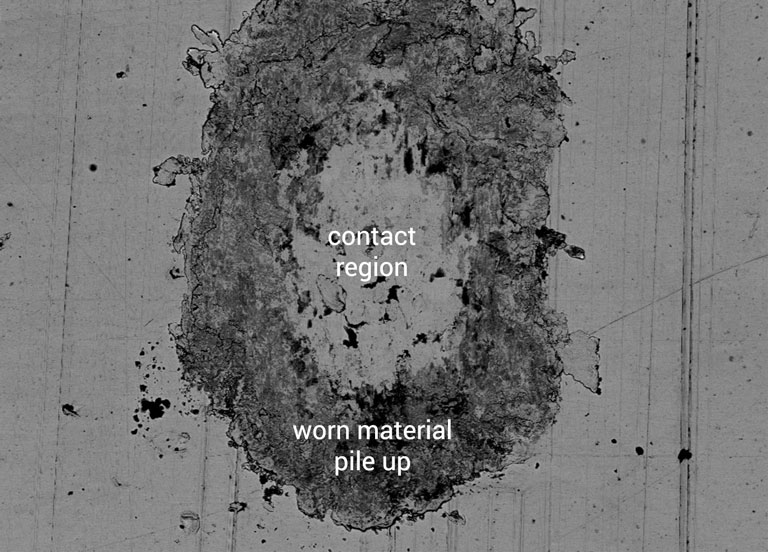

- Fretting

For the counter-electrode, we can choose between round-headed or flat-headed rivets as well as several typical contact materials.

Contact for questions

Dr.-Ing Dominik Britz

Deputy Head MECS Saarbrücken

Adrian Thome, M. Sc

Project Leader

Further areas of application

Machine Learning (ML)

Our services range from feasibility studies with our various approaches to exploratory data analysis with unsupervised ML.

Correlative Microscopy

A correlative characterization of microstructures serves as a benchmark for automated microstructure recognition and as a starting point for machine learning approaches.

Failure analysis

In the area of failure analysis, in addition to identifying and analyzing causes of fracture, we are also able to fully characterize components on both the macro and micro scales.

Antimicrobial surfaces

Our antimicrobial metallic surfaces have already been used in 3 research projects with ESA & NASA on the ISS.